navigation

日本SUMITOMO住友减速机CHHM10-6185-B-87 CHHM2-6135DC-143

Cyclo® 6000 Gearmotor

Our best-selling gearmotor with high strength and reliability, thanks to its unique Cyclo® mechanism.

With its long history and delivery record, it has become synonymous with the term speed reducer.

Unique Cyclo® mechanism results in high durability and extended operating life.

Wide variety of products available that take advantage of this technology.

Select the best product to meet your needs from a wide range of capacities and reduction ratios.

500 %

Shockload capacity. The highest in the industry.

2 Year

Warranty on all Cyclo Products.

658,503 :1

Available in standard offerings. Larger ratios available upon request.

Product Features

Avoid Catastrophic Failure

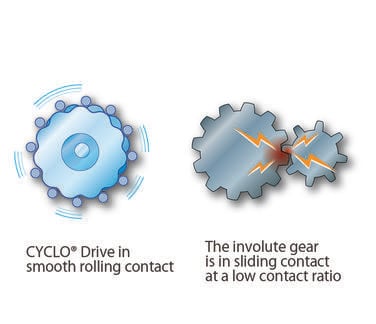

The cycloidal disc design allows the reduction components to operate in a smooth, rolling manner, preventing tooth breakage typical in conventional gearing, and resulting in a durable product with a long life.

Wide Capacity Range

Choose the size and modifications that best fit your needs. A wide range of HP ratings up to 200HP, reduction ratios up to 658,503:1, and dozens of application and industry specific modifications, ensure your operation avoids unexpected downtime.

Industry Leading Service Factors

Due to the Cyclo design, service factors out pace normal AGMA recommended service factors by nearly 25%. This allows you to downsize when selecting a Cyclo, while still maintaining the same ratings and service factors you are accustomed to with conventional gear reducers.

Maintenance Free Options

Rolling elements result in less friction and less heat. Subsequently, this allows us to utilize grease lubrication in an effort to provide you with a nearly maintenance free solution. Grease lubrication comes standard in sizes 6060 to 6125, and is optional in sizes 6130 and above.

Bearing Grade Steel

Unlike conventional in-line gear reducers utilizing helical or planetary gearing, all of the Cyclo's reduction components are made of high quality 52/100 bearing-grade steel.

Compact and Torque Dense

With single reduction ratios up to 121:1, we can offer single stage reducers where others must move to two or three stages. This allows for a compact offering, saving you money and space, as well as a efficiency gains compared to multi-stage reducers.

Break-Resistant Gearing

Unlike a regular involute tooth-gear, the "cycloidal disc," which is the gear for the Cyclo® Reducer, features a distinctively smooth curve.

A unique circular-arc tooth profile is also used for the internal gear. The smooth rolling contact that prevents tooth breakage results in a durable gearbox with a long service life. (Some low reduction ratio models use helical gears and planetary gears.)

所有产品分类

所有产品分类

友情链接Link

友情链接Link